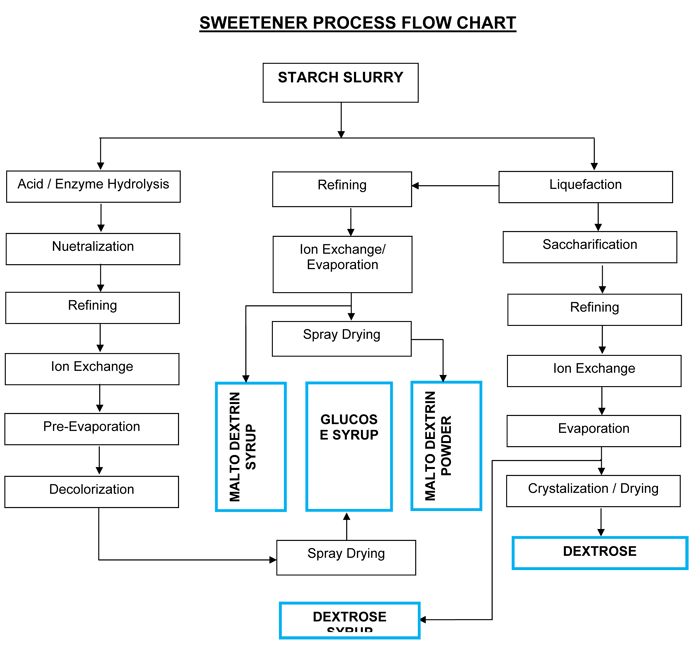

Glucose syrup is prepared by both acid and enzyme process. In acid process the starch slurry is prepared for conversion by adjusting the pH and concentration and fed to the continuous indirect acid convertor and the temperature, DE value is auto controlled to get continuous output of desired DE value. The obtained syrup is neutralized, filtered to remove mud and protein impurities and then passed through ion exchange column to remove the ionic impurities and reduce the ash content and finally concentrated to 82~86% DS in triple effect evaporator.

Whereas in enzyme hydrolysis the slurry is prepares by adding enzyme and pH adjustment and passed through jet cooker system wherein direct steam and slurry get in contact and heat and convert starch into glucose, the syrup is hold in holding columns for 2 hours and neutralized and taken into saccharifcation tanks for second enzyme dosing and further DE value is increased to desire level, filtered to remove protein and passed thorugh ion exchange columns to remove ionic impurities and reduce the ash content and concentrated to 82~86% DS in triple effect evaporator.